TM 9-6115-604-34

NAVFAC P-8-633-34

NOTE

Cylinder head weight is approximately 63 pounds (28 kg). Two

persons may be required to lift cylinder heads.

(a)

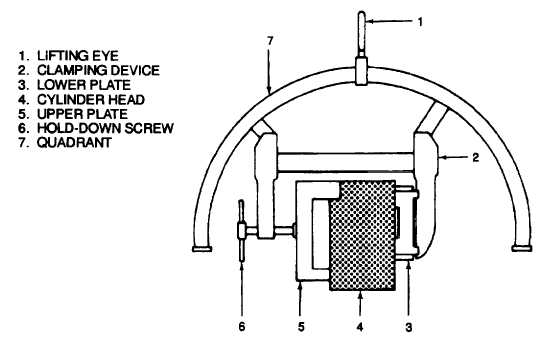

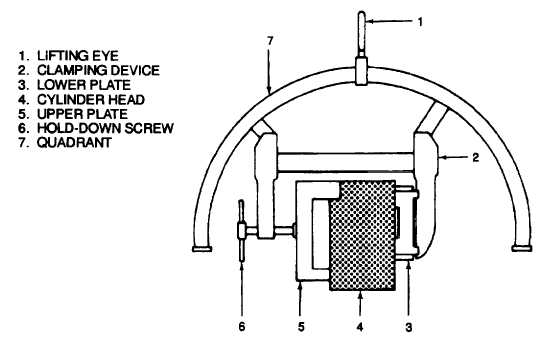

Position the head and test fixture ST-1012 over a water tank of sufficient capacity to completely

submerge the head.

(b)

Connect an air supply of 30 to 40 psi (207 to 276 kPa) to test fixture ST-1012 and submerge the

head in water.

(c)

Leaks are indicated by the presence of air bubbles. Check carefully around the area of the

expansion plugs, pipe plugs, valve seats, and injector seal seat for leaks or cracks.

(2)

Assemble the head in test fixture ST-1012, as in step (1), above, (Figure 9-5), and perform a water

pressure test as follows:

(a)

Position the head over a drain area and connect a water supply at 35 to 85 psi (241 to 586 kPa),

and a temperature of 180° to 200°F (82° to 93° C). Close the water outlet, and inspect the same

areas as in step (1) (c), above, for water leaks.

(b)

Open the water outlet of the test fixture, and check for free water circulation through the coolant

passages. If the water flow is restricted, the pipe plugs and expansion plugs must be removed

and the water jacket cleaned in accordance with paragraph 9-11.

(c)

Replace leaking expansion plugs in accordance with paragraph 2-10.

(d)

Remove damaged or leaking pipe plugs, install new plugs using sealant MIL-S-45180, Type IIl,

and re-test for leaks.

(3)

Using magnetic crack detector ST-1166 or equivalent, check for cracks in the area of the valve ports

and injector port. Discard the head if cracked.

(4)

Visually inspect the head for damaged gasket surfaces and eroded water holes that would interfere

with proper gasket sealing. Refinish damaged gasket surfaces and repair eroded water holes in

accordance with paragraph 9-11.

(5)

Inspect dowel pins for damage and tightness of fit, and check threaded holes for damage or stripping.

Repair stripped holes in accordance with paragraph 2-12.

(6)

Check the soundness of the expansion plugs by tapping them with a sharp punch. Replace expansion

plugs that dent easily, or are penetrated easily, in accordance with paragraph 2-10.

Figure 9-5. Cylinder Head Installed In ST-1012

9-10