TM 9-6115-604-34

NAVFAC P-8-633-34

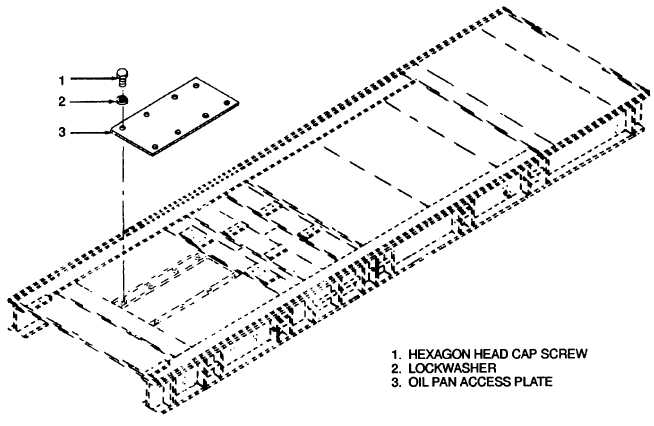

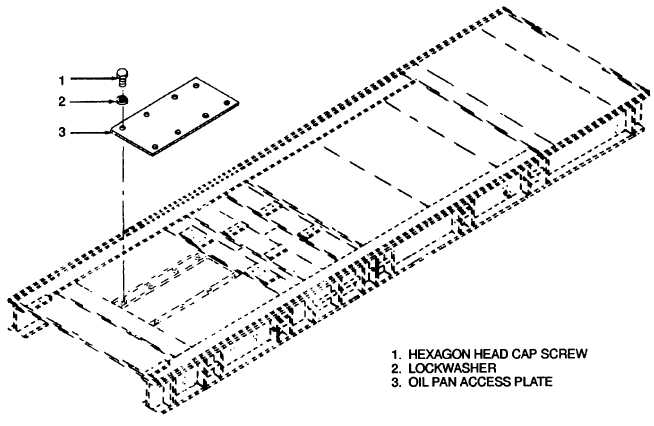

Figure 8-3. Removal and Installation of Oil Pan Access Plate

8-11.

OIL PUMP CLEANING AND INSPECTION. See Figure 8-4.

WARNING

Dry cleaning solvent, PD-680, Type Ill, or equivalent, is flammable

and moderately toxic to the skin, eyes, and respiratory tract.

Assure adequate ventilation. Skin, eye, and respiratory protection

is required to avoid Injury to personnel.

WARNING

Compressed air used for cleaning or drying can create airborne

particles that may enter the eyes. Pressure shall not exceed 30 psi

(207 kPa). Wearing of goggles is required to avoid injury to

personnel.

a.

Clean all parts using cleaning solvent PD-680, Type lII, or equivalent, and dry with compressed air.

b.

Inspect the pump gears (41, 43, and 44), and replace them if the teeth are chipped or cracked, or if the thrust

surfaces are scored deeper than 0.003 inch (0.08 mm).

c.

Inspect the lubricating pump shafts (42 and 45) and replace them if they are scored deeper than 0.003 inch

(0.08 mm), or worn smaller than 1.4993 inches (38.082 mm) in the bushing wear area.

d.

Measure lubricating pump bushings (46) in the cover (39) and body (47). Replace them if they are worn

larger than 1.505 inches (38.22 mm).

e.

Check the gear pockets in the lubricating pump body (47). If the finished surfaces are scored deeper than

0.003 inch (0.08 mm), replace the body.

8-7