TM 9-6115-604-34

NAVFAC P-8-633-34

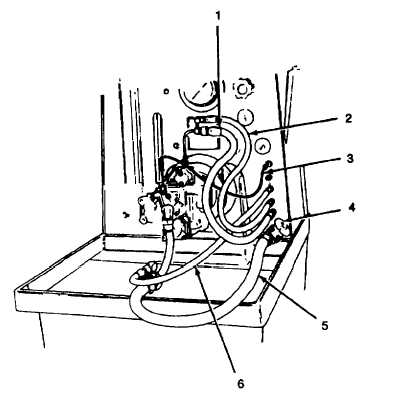

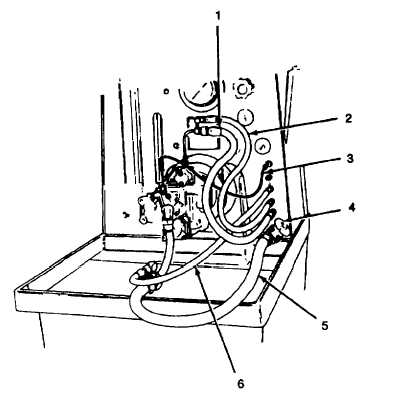

1.

OUTLET HOSE

4.

SUCTION VALVE

2.

HOSE TO PRESSURE GAGE

5.

SUPPLY HOSE

3.

RETURN HOSE

6.

HOSE TO VACUUM GAGE

Figure 6-16. Test Stand Hose layout

(10)

Loosen the adjusting screw nuts (25 and 27, Figure 6-11) and back out the setscrews (28) completely so

that they do not interfere with the free movement of the throttle shaft stop (34) on the throttle shaft (30).

(11)

Lightly damp a pair of locking pliers on the throttle shaft (30), and install a universal spring to hold the

throttle shaft in the fully open position (rotated fully clockwise) as in step (9), above.

(12)

Open the suction valve (4, Figure 6-16), set the rotation switch (2, Figure 6-17) for right hand rotation, and

press the start/stop light button (16).

(13)

Using speed control handle (4, Figure 6-15), adjust the pump speed to 500 rpm, and check the vacuum

gage (7, Figure 6-17) to be sure the fuel pump has suction. If the vacuum gage (7) does not indicate

suction, stop rotation and repeat step (5), above.

(14)

Increase the pump speed to 1700 rpm, and adjust the suction valve to give vacuum gage (7) reading of 8

inches (200 mm) Hg.

(15)

After 2 or 3 minutes of running time, check the main flowmeter (15) for the presence of air bubbles.

NOTE

It will take 2 to 3 minutes for the fuel pump to become completely primed and expel all air.

During this time, the presence of air bubbles in the main flowmeter is normal.

(16)

If the bubbles persist after 2 to 3 minutes of running time, a vacuum leak is indicated. Check and repair

vacuum leaks in the suction hoses before continuing.

(17)

Run the pump for 30 minutes and any additional time necessary to reach a test oil temperature of 90° to 1

000F (320 to 38"C) on fuel temperature gage (1).

6-35