ARMY TM 5-6115-633-14&P

CHAPTER 3

OPERATOR/CREW MAINTENANCE INSTRUCTIONS

Section l. CONSUMABLE OPERATING AND MAINTENANCE SUPPLIES

3-1.

Consumable Supplies. Consumable supplies used in the maintenance and operation of the

power plant are listed in Table 3-1.

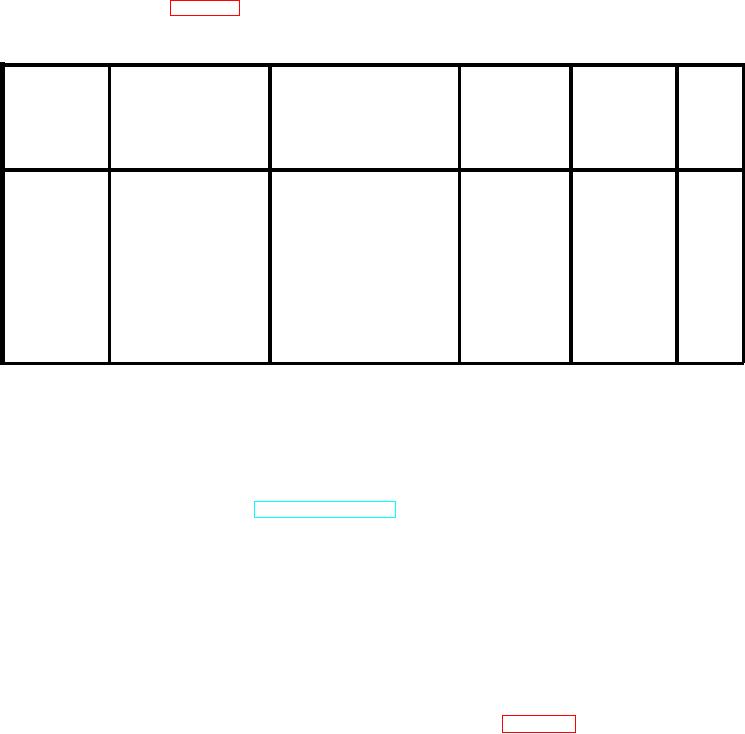

Table 3-1. Consumable Operating and Maintenance Supplies.

(4)

(2)

(5)

(6)

(3)

(1)

Qty

Qty

required

National

required

for initial

stock

8 hours

Component

number

Description

operation

operation

Notes

application

1 quart

As required

6850-00-664-5685

Solvent, Drycleaning,

General

P-D-680

Cleaning

1 pound

As required

9150-00-190-0904

Grease, Automotive and

Leg Prop

Artillery, GAA

Assembly

1 quart

As required

9150-00-186-6681

Oil, Lubricating,

Leg Prop

OE/HDO-30

Assembly

1 quart

As required

Oil, Lubricating, OEA

9150-00-402-4478

Section Il. LUBRICATION INSTRUCTIONS

3-2. General. Detailed instructions for the lubrication of the major components of the power plant are

contained in the applicable Lubrication Orders (LO's). Refer to DA Pam 310-1 to ensure that the latest

editions of the LO's are used.

3-3. Generator Lubrication. Refer to TM 5-6115-585-12 for generator set Lubrication Order.

3-4. Trailer Lubrication. There are no operator/crew lubrication requirements for the power plant

trailer. However, the operator shall assist unit maintenance.

Section Ill. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

NOTE

The PMCS chart in this section contains all necessary Operator/Crew

preventive maintenance checks and services for this equipment.

3-5. General. The preventive maintenance checks and services listed in Table 3-2 are grouped

according to stages of equipment operation or time intervals. Using the following as a guide, do the

checks and services at the intervals shown.

a. Before you operate, perform your before (B) PMCS. Observe all CAUTIONS and WARNINGS.

3-1