a. See figure 14-16 and connect the electric

starter in the no-load test circuit illustrated. Per-

form no-load test as follows:

(1) Energize the test circuit and obtain a voltage

of 22 volts by varying the variable resistance.

(2) Check the speed of the armature on the

tachometer.

Minimum speed should be 7000 rpm.

(3) Check the current draw on the ammeter.

Maximum current draw should be 90 amperes. If a

low-speed, high-current condition exists, possible

causes are excessive armature arcing, armature

ground, armature short, or armature drag caused

by loose pole shoes or faulty bearings. A low-speed,

low-current condition indicates faulty brushes or

faulty connection.

b. See figure 14-16 and setup for lock torque

ted as illustrated.

CAUTION

Never operate the electric starter with all

resistance removed from the circuit. Fail-

ure to adhere to this caution will result in

extreme motor speeds which can cause

damage to the motor and possible injury to

personnel.

The variable resistance should be

one with a high current capacity.

(1) Energize the circuit and check the scale to

determine the torque output of the motor.

(2) Scale should indicate 22 pound-feet (mini-

mum), at 400 amperes and approximately four volts,

as indicated on the meters.

C. Installation. Install the starter motor on the

flywheel housing using the disassembly steps in re-

verse order. See figure 14-9.

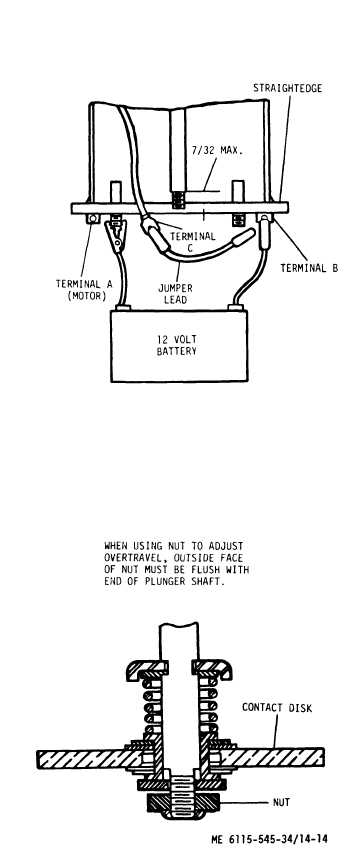

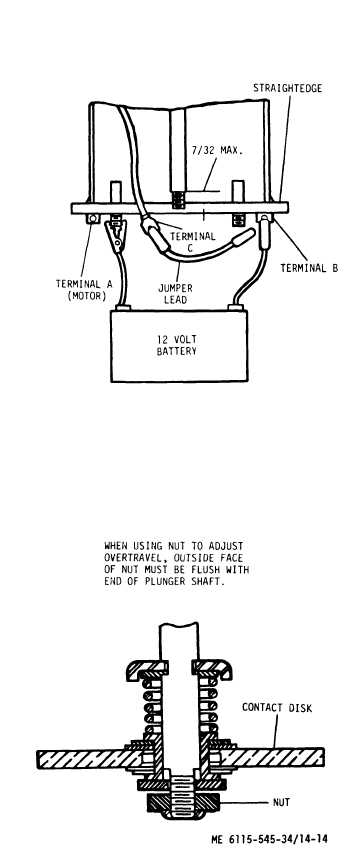

Figure 14-14.

Solenoid Adjustments

14-21