2-5. Installation and Setting-up Instructions.

a . General. The engine generator set should be

installed on a level site, clear of obstacles, and with

ample ventilation.

The site must be within 25 feet

of any paralleled generator set, 25 feet of any auxi-

liary fuel supply and 500 feet of any remote control

area.

b . Outdoor Installation. When preparing for a

permanent installation, be sure the base is solid

enough to support the weight of the unit. See figure

2-1 for dimensions of the base. Select a location

where there will be sufficient space on all sides for

servicing and operation of the engine generator set.

When preparing a temporary installation, move the

engine generator set as close to the worksite as

practical. Use suitable planks, logs, or other

material for a base in an area where the ground is

soft .

c. Indoor Installation. Keep the area well venti-

lated at all times, so that the engine generator set

will receive a maximum supply of air. If a free

supply of fresh air is not available, provide duct

work, with an opening at least as large as the radiator,

to the outside of the installation. If louvers are used

at the air entrance, increase the duct work size by

25 to 50 percent.

Loosen the screw and nut which

secure the weather cap to the exhaust outlet and re -

move the weather cap. Install a gas-tight metal pipe

exhaust from the exhaust outlet to the outside of the

installation.

The termination of the exhaust pipe

shall be such that hot gases or sparks will be dis -

charged harmlessly and will not be directed against

combustible material or into an area containing

flammable gases or vapors. Use as few bends in

the pipe and as short a pipe as possible. The ex-

haust pipe should include a low point with suitable

means for draining of condensate. Provide metal

shields, 12 inches larger in diameter than the ex-

haust pipe where the line passes through flammable

walls. Wrap the exhaust pipe with asbestos if there

is any danger of anyone touching it. Refer to figure

2-1 for dimensions, air flow requirements and floor

loading requirements.

WARNING

Do not operate the engine generator set in an

enclosed area unless the exhaust gases are

piped to the outside. Inhalation of exhaust

fumes will result in serious illness or death.

d. Leveling,

The engine generator set is a

portable unit and is designed to operate satisfactorily

up to 15° out-of-level. Set up the unit as level as

possible and keep it as level as possible during

operation.

e. Grounding. The engine generator set must be

grounded prior to operation. The ground can be, in

order of preference, (1) an underground metallic

water piping system, (2) a driven metal rod or

(3) a buried metal plate (fig. 2-2). If the effectively

grounded portion of the buried metallic water pipe

is less than 10 feet due to insulated sections or

joints, this preferred grounding method must be

supplemented by an additional driven metal rod

ground or a buried metal plate ground. A driven

metal ground rod must have a minimum diameter

of 5/8 inch if solid or 3/4 inch if pipe, and driven

to a minimum depth of 8 feet. A buried metal

ground plate must have a minimum area of 9 square

feet, minimum thickness of 1/4 inch, and be buried

at a minimum depth of 4 feet. The ground lead

must be at least No. 6 AWG (American Wire Gauge)

copper wire. Ground rods are available as optional

equipment. The procedures for making a ground

connection are shown in figure 2-2.

f. Generator Load Connections. Instructions

for making the required generator load connections

are designated in figure 2-3.

2-6. Equipment Conversion.

a. Conversion instructions for equipment opera-

tion at 120/208 Vac or 240/416 Vac are given in

figure 2-4.

b . Conversion instructions for equipment opera-

tion of 50 or 60 Hz are given in figure 2-6.

c. Conversion instructions for remote operation

by removal and relocation of the control cubicle are

given in paragraph 2-23.

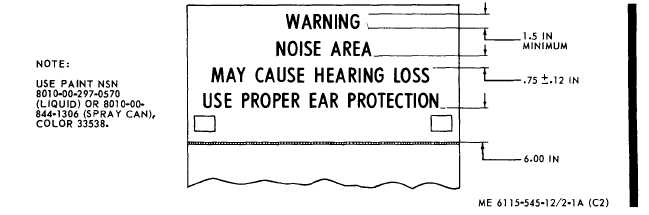

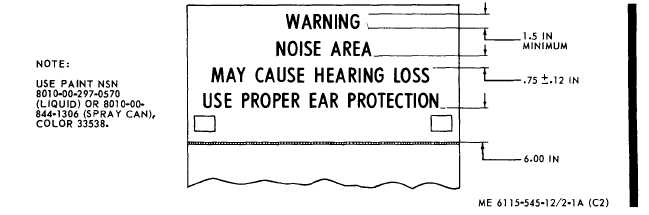

Figure 2-1A. Noise level warning.

Change 2

2-3