TM 5-6115-465-34

TO 35C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

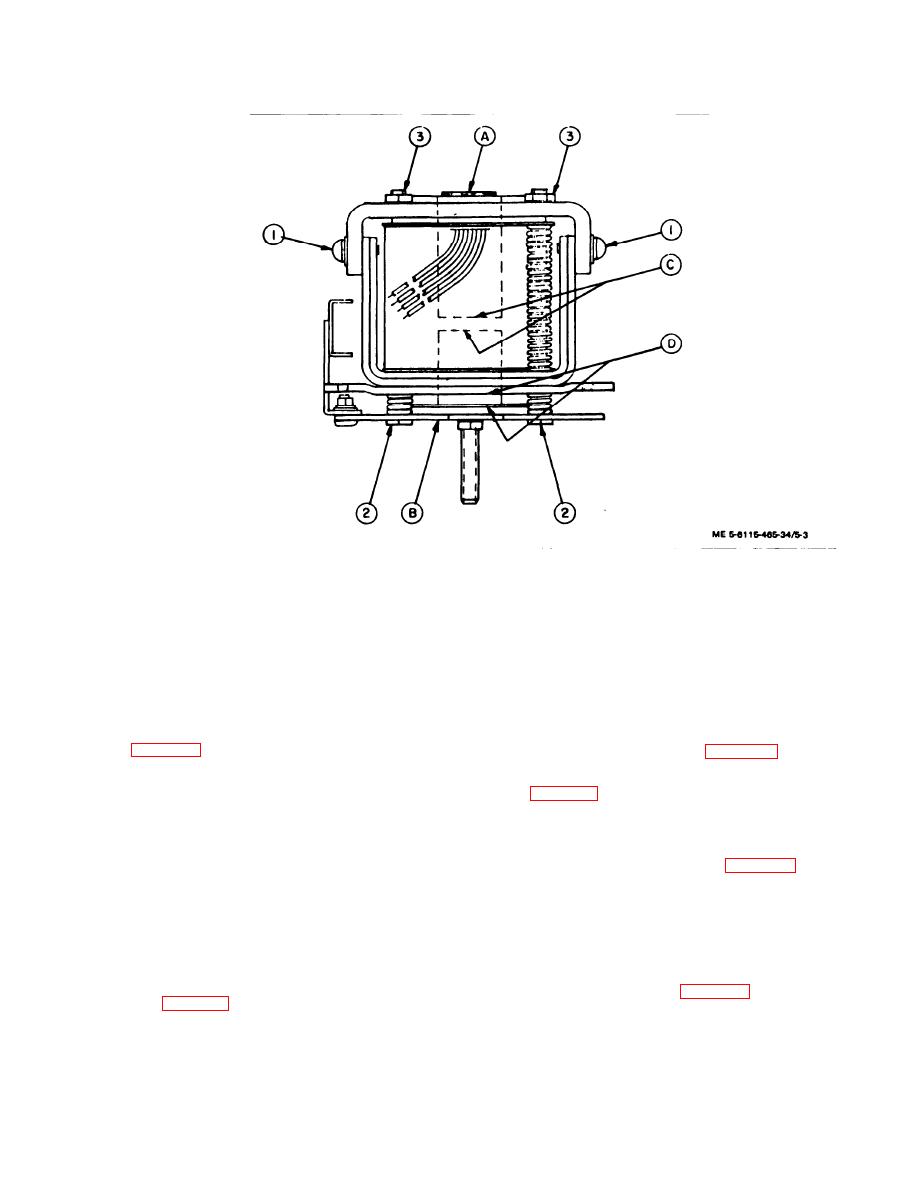

Figure 5-3.

Actuator Assembly Adjustment Points

(d) Insert a 0.150 0.010 inch feeler

NOTE

gauge into the movable core gap.

Preload is checked by the initial break-

(e) Adjust guide rods (2) until the gauge

away of retaining ring (point (B)).

is snug throughout the parimeter.

(a) Using a force gauge, check each in-

(f) Secure the adjustment by tightening

dividual contact at its edge (point (A)). Preload

loosely installed nuts (3).

should be 1.5 to 205 pounds.

(12) Install contact assemblies (54 and 53,

(b) If preload is not as specified, add or

subtract shims (26, 29, and 30, figure 5-2).

washer (51), lockwasher (50), screw (49), lock-

washers (46), and screws (47).

(17) Install actuator and connector assembly

(45, figure 5-2) onto main base (46) and secure with

(13) Secure contact assemblies (38) to main

bushing (44), lockwashers (43) and screws (42).

base (46) with flat washers (37), lockwashers (36),

and nuts (35). Install terminal washers (41), lock-

(18) Install main contact assembly (23) and

washers (40) and nuts (39).

secure with lockwashers (22) and nuts (21). Adjust

contact over travel as follows: (See figure 5-5. )

(14) Install grommets (33), spacers (34), and

arc chutes (32).

(a) Attach an ohmmeter to terminals

A1-A2 ad C1-C2.

(15) Install shims (30 and 29), springs (28),

bushings (27), and shims (26) onto bridge assemblies

(b) Insert a 0.035 inch feeler gauge into

(25). Secure bridge assemblies to main contact

core gap (point (A)).

operator (31) with retaining rings (24).

(c) Energize coil by applying 24 Vdc across

(16) Check preload of each contact as follows:

connector pins A and B (see figure 5-6).

(See figure 5-4. )

5-7