TM 5-6116-465-34

TO 35C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

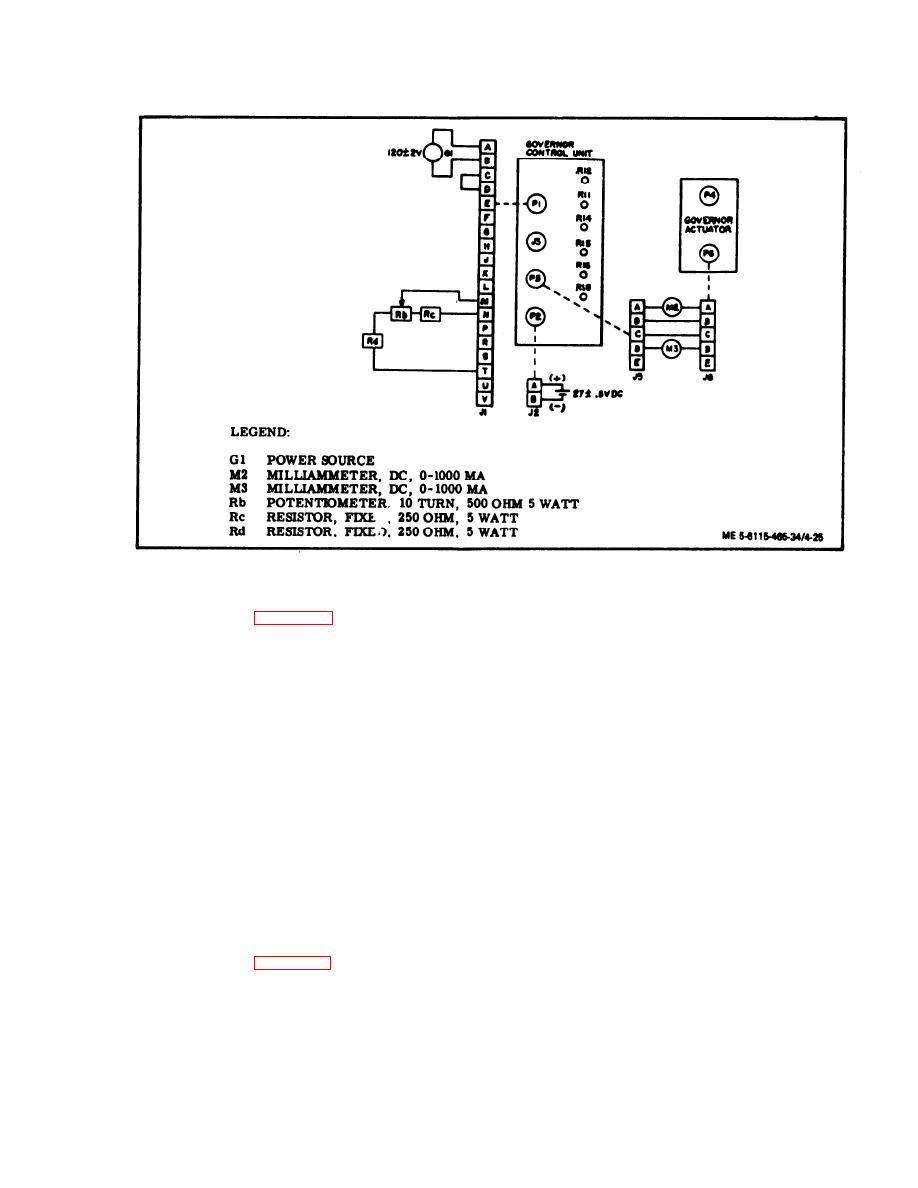

Governor Control Unit Frequency Sensing Test Circuit

Figure 4-25.

(c) Reverse polarity of connections to

(a) Install governor control unit in test

pins J1-E and J1-G.

circuit as shown in figure 4-28.

(d) M2 shall indicate 600 to 840 milliamp-

(b) Turn R14 and R15 to full counterclock-

eres. M3 shall indicate 0 to 300 milliamperes.

wise position.

(c) M5 shall indicate -5 to -7 milliamp-

h.

Potting.

eres.

(1) Check all connections and if any have been

bored for test purposes, or if any defective compon-

(d) Adjust R14 clockwise until indication

ents have been replaced, the effected area and com-

and M2and M3 are balanced.

ponents must be coated with polyurethane resin to

(e) Place SWl in the LOW position M3

prevent oxidation or other corrosion The coating

shall indicate 600 to 840 milliamperes. M3 shall in-

must be of a minimum thickness of 0.007 inch and air

dicate 0 to 300 milliamperes. M5 shall indicate less

bubble entry so the applied polyurethane must be

than 0 to +1.5 milliamperes.

controlled so that the legibility of component coding

and identification is not impaired.

(f) Place SWl in the HIGH position M3

shall indicate 0 to 300 milliamperes. M3 shall indi-

(2) Check connections of printed circuit board

cate 600 to 840 milliamperes. M5 shall indicate

to cover.

less than 0 to -1.5 milliamperes.

(3) Place the container in a temperature con-

trolled oven. Set the oven temperature at +180 to +185

(6) Perform parallel winding test as follows:

F (+82.2 C to + 85 C) and allow the container to soak

11 to 12 hours or until potting compound is completely

(a) Install governor control unit in test

melted.

circuit as shown in figure 4-27.

.

(4) Prior to installing the printed circuit board,

remove the container from the oven and make sure that

(b) M2 shall indicate 0 to 300 milliamp-

insulation paper is positioned next to the container

eres. M3 shall indicate 600 to 840 milliamperes.

shell,

4-35