TM 5-6115-465-34

TO 35C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

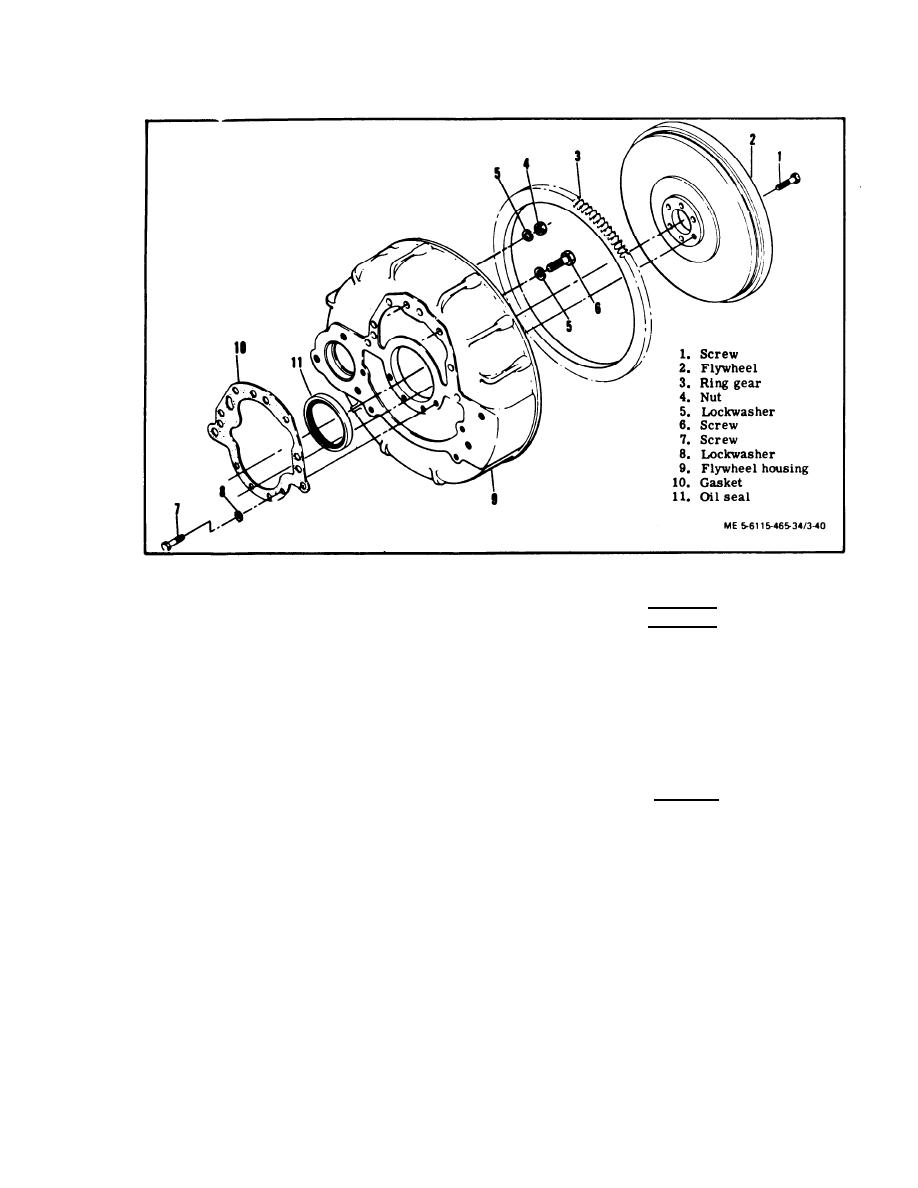

Figure 3-40.

Flywheel and Flywheel Housing, Exploded View

WARNING

(6), screws (7) and lockwashers (8) to remove fly-

wheel housing (9) and gasket (10). Discard gasket.

Wear asbestos gloves when handling heated

flywheel to avoid serious burns.

(4) Using a suitable press, remove oil seal

(11) from fywheel housing and discard.

(b) Remove flywheel and ring gear and

b. Cleaning, Inspection, and Repair.

lightly tap ring gear to separate.

(1) Clean all parts in dry cleaning solvent

(c) Heat replacement ring gear as in step

(Federal specification P-D-680) and dry thoroughly.

(3)(a) above while freezing flywheel.

Remove caked grease deposits with a stiff bristle

brush.

CAUTION

(2) Inspect flywheel for cracks, nicks, and

burrs. Remove minor nicks and burrs with crocus

Wear asbestos gloves when handling frozen

cloth.

flywheel and heated ring gear.

NOTE

(d) Quickly install heated ring gear onto

frozen flywheel.

Rinse flywheel in dry cleaning fluid after

dressing with crocus cloth. Crocus cloth

(4) Inspect flywheel housing for cracks, ex-

contains ferrous oxide which will acceler-

cessive corrosion, and defective paint.

ate rusting of cast iron parts.

(5) Repair cracks in flywheel housing by weld-

(3) Inspect ring gear for cracks, chipped or

ing.

broken teeth and other damage. If ring gear is badly

(6) Remove corrosion from flywheel housing

damaged, replace as follows:

with No. 00 grit abrasive paper soaked in oil. Clean

flywheel housing with dry cleaning solvent after re-

(a) Heat flywheel and ring gear in an

moving corrosion.

oven at 450F (232.2C) for two hours.

3-63