T.O. 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-07464A-35

NOTES:

1. COIL DATA:

A. WIRE SIZE: . 064 DIA (#14 GA) CLASS 155, TYPE L2.

B. NUMBER OF WIRES PER TURN: 10

c . NUMBER OF TURNS PER COIL: 3

D. NUMBER OF WIRES PER COIL: 30

E. COIL GROUPING: 12 GROUPS OF 6 COILS.

F. COIL SPAN: SLOTS 1 AND 13.

2. STATOR WINDING PROCEDURE:

A. WIND COILS TO PROPER SHAPE, SPECIFIED DIMENSIONS AND NUMBER OF TURNS.

B. HOLD COILS TOGETHER WITH TAPE, INDEX 9.

c . APPLY SLEEVING, INDEX 11, AND INDEX 8, (LOOSE).

D. SELECT AN ARBITRARY SLOT ON CORE, INDEX 1, AND INSERT FIRST COIL GROUP WITH START

LEAD IN THE BOTTOM OF SLOT NO. 1 AND THE ENDING LEAD IN THE TOP OF SLOT NO. 13.

(COIL SPAN 1 AND 13).

E. INSERT THE NEXT COIL GROUP PER ABOVE GROUPING SEQUENCE. INSERT PHASE INSULATION,

INDEX 10, DURING PLACING OF COILS. REPEAT SEQUENCE UNTIL WINDING IS COMPLETE.

F. MAKE PHASE CONNECTION PER CONNECTION DIAGRAM (HOMOGENEOUS WELD).

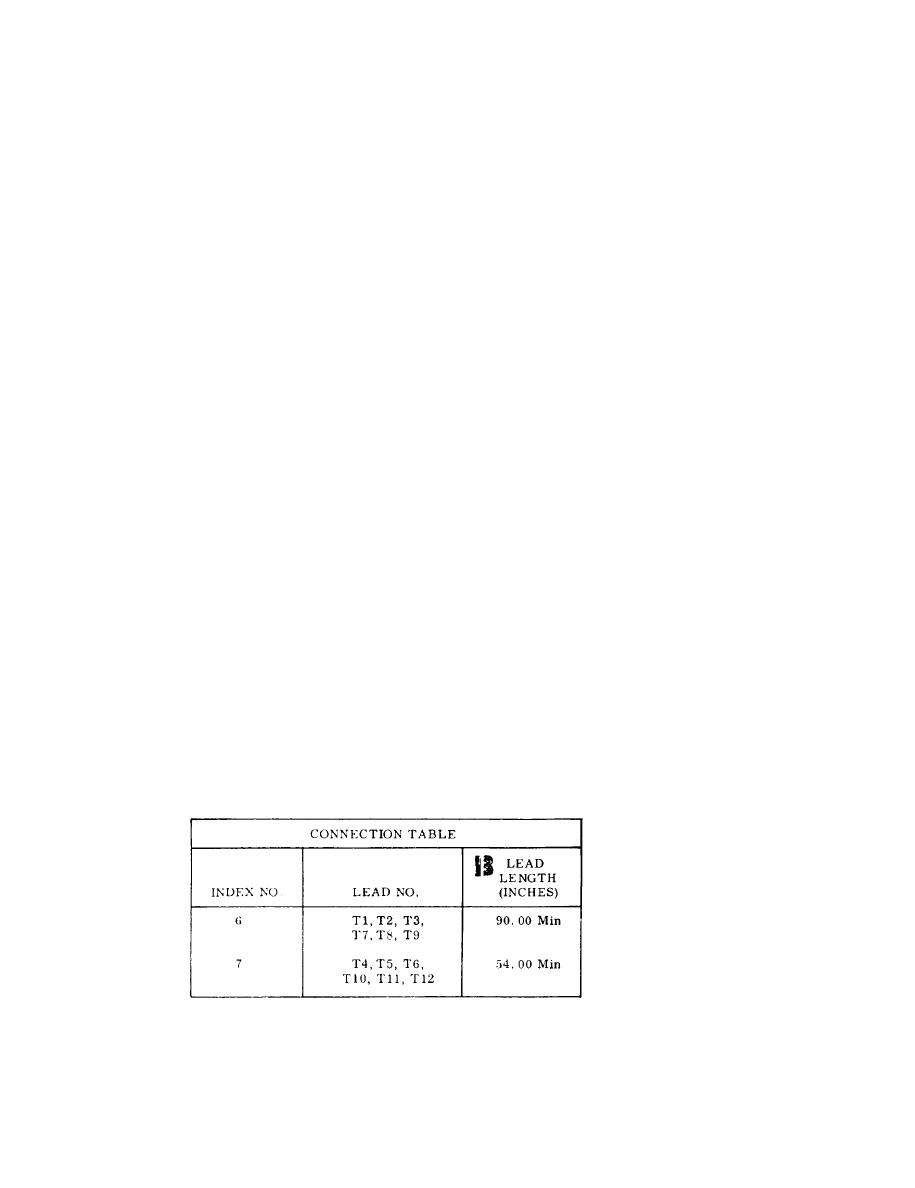

G. CONNECT LEADS, INDEX 6 AND 7 INDIVIDUALLY AND ISOLATED FROM EACH OTHER WITH

INDEX 8 PER CONNECTION TABLE (HOMOGENEOUS WELD WIRE ENDS).

H. APPLY SLEEVING, INDEX 8, OVER LEAD, INDEX 6 AND 7, CONNECTIONS AND PHASE CON-

NECTIONS.

J. WRAP WINDING WITH TAPE, INDEX 9.

3. VARNISH AS FOLLOWS:

STEP 1: PREBAKING -

PUT INTO OVEN AT 110 C(230 F) HOLD AT TEMPERATURE FOR 4 HOURS. COOL TO

APPROXIMATELY 50 C(122 F).

STEP 2: DIPPING -

IMMERSE IN VARNISH, MIL-1-24092, UNTIL BUBBLING CEASES. VISCOSITY SHALL BE

HELD TO 60 ZAHN SECONDS USING NO. 2 CUP. THIN WITH SOLVENT, MIL-N-15178,

TYPE A/B.

STEP 3. DRAINING -

DRAIN AND AIR DRY FOR 1 HOUR. ROTATE WOUND APPARATUS TO PREVENT POCKETING

THE VARNISH.

STEP 4: WIPING -

AFTER DRAINING BUT BEFORE BAKING, THE METAL SURFACES OF THE ARMATURE, THE

BORE OF THE STATOR AND THE POLE FACES OF THE FIELD STRUCTURE SHALL BE

WIPED WITH A CLOTH MOISTENED WITH SOLVENT, MIL-N-15178, TYPE A/B.

STEP 5: BAKING -

BAKE IN CIRCULATING TYPE, FORCED EXHAUST, BAKING OVEN AT TEMPERATURE OF

165 C(329 F),

STEP 6: COOLING -

REMOVE FROM OVEN AND COOL TO APPROXIMATELY 50 C(122 F).

STEP 7: SECOND TREATMENT (DIP IN OPPOSITE DIRECTION) - REPEAT STEPS 2 (IMMERSE FOR 1

MINUTE)> 3, 4, 5, AND 6,

STEP 8: THIRD TREATMENT (DIP IN ORIGINAL DIRECTION) - REPEAT STEPS 2 (IMMERSE FOR 1

MINUTE), 3, 4, 3, AND 6.

4. STAMP PART NUMBER AS SHOWN BELOW PER MIL-STD-130, 0.12 MIN HEIGHT, USING WHITE

ENAMEL PAINT.

5. AFTER REWINDING, PERFORM INSPECTION SPECIFIED IN 7-5, STEPS K AND 0.

Figure 7-2.

50/00 Hertz generator, main stator rewind data (sheet 2 of 2)

7-10