LUBRICATION

L05-6115-575-12

ORDER

29 AUGUST 1975 (Supersedes L05-6115-575-12 Dtd 2 OCT 1970)

GENERATOR SET, DIESEL ENGINE DRIVEN: LIQUID COOLED, AC,

100KW, 120/208, 240/416 VOLT 3 PHASE, 50/60 HZ, SKID

MOUNTED: (JETA POWER MODEL D8001M) W/ENGINE

ALLIS-CHALMERS MODEL 11000

Reference: FEDERAL SUPPLY CATALOG C9100-IL

Intervals are based on normal hours of operation. Adjust

WARNING

to compensate for abnormal operation and severe

conditions or contaminated lubricants. During inactive

Dry cleaning solvent, P-D-680, used to clean parts is

periods, sufficient lubrication must be performed for

potentially dangerous to personnel and property. Avoid

adequate preservation.

repeated and prolonged skin contact. Do not use near

open flame or excessive heat. Flash point of solvent is

Clean fittings before lubricating.

100 degrees F. (380 C.) - 138 degrees F. (590 C.).

Clean parts with SOLVENT, dry-cleaning (Federal

Relubricate after washing.

Specification P-D-680). Dry before lubricating.

The time specified is the time required to perform all

Drain crankcase only when hot after operation; replenish

services at the particular interval.

and check level when cool.

FOLD

FOLD

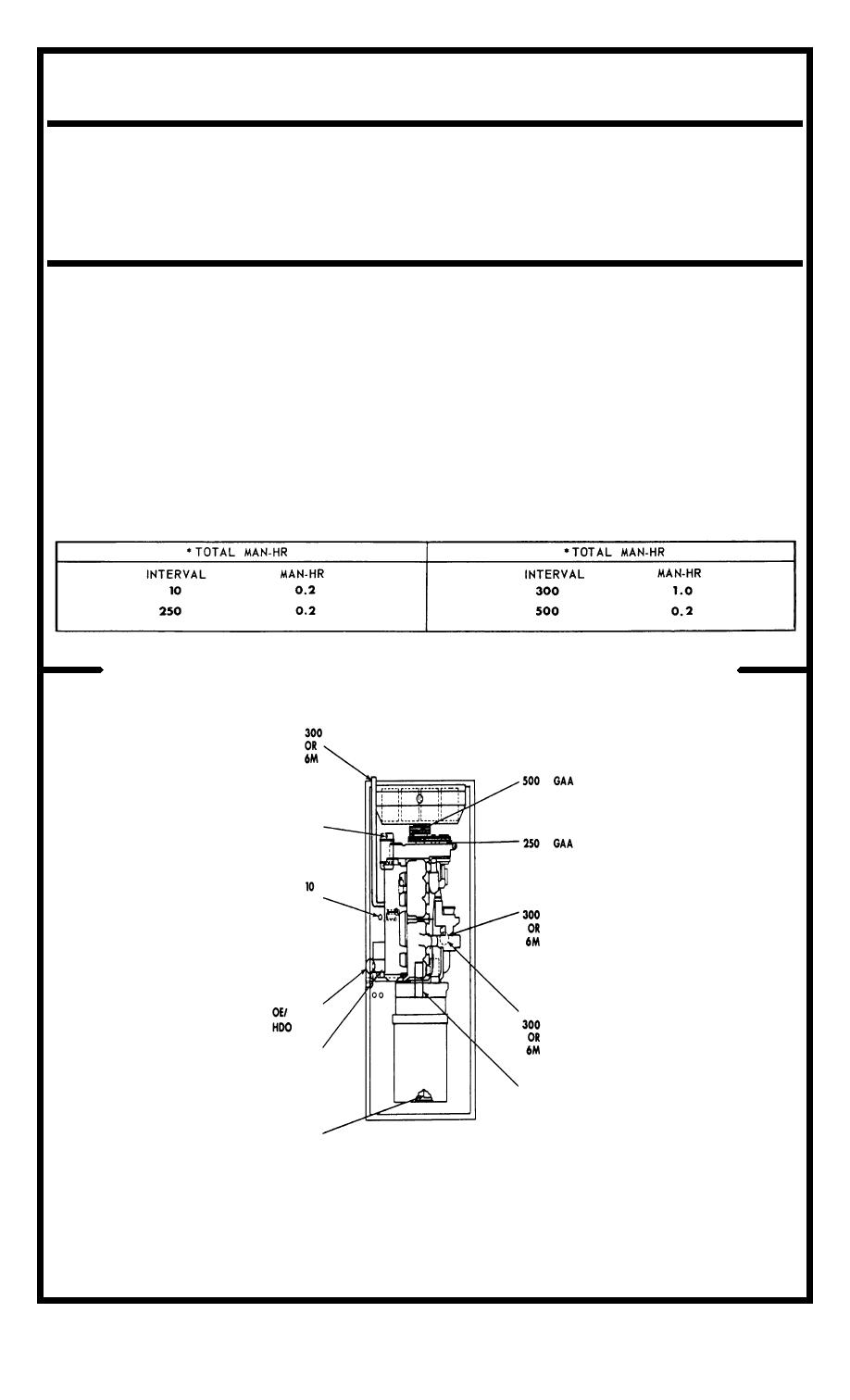

LUBRICANT l INTERVAL

INTERVAL l LUBRICANT

Crankcase Oil Drain

Hose

(Remove plug to drain)

(Drain and refill)

Fan Hub

(Sparingly)

Engine Generator

(Sealed bearing no

lubrication required)

Water Pump

(Sparingly)

Crankcase Oil Level

Gage

(Check level)

Oil Filter

CAUTION: When OEA

(Disassemble, clean

Oil is used the level

housings, renew ele-

will be checked more

ments, and reassemble.)

often. (See note 4)

(See note 2.)

Oil Filter Drain Plugs

Crankcase Oil Fill Cap

(Drain and reinstall

(See key)

plugs)

Starter

(Sealed bearings, no

lubrication required.)

Air Cleaner

(Dry type no lubrica-

(Dry type no lubrica-

tion required)

Main Generator

(Sealed bearing, no

lubrication required.)