LO 5-6115-457-12

LUBRICATION ORDER

LO-07464A-12

20 JANUARY 1988

( S u p e r s e d e s LO5-6115-457-12, 21 N o v e m b e r 1 9 8 6 )

GENERATOR SET, DIESEL ENGINE DRIVEN SKID MTD., 100 KW,

3 PHASE, 4 WIRE, 120/208 AND 240/416 VOLTS

DOD MODEL

CLASS

HERTZ

NSN

MEP007A

UTILITY

50/60

6115-00-I 33-9101

MEP106A

PRECISE

50/60

6115-00-l 33-9102

MEP11A

PRECISE

400

6 115-00-I 33-9 103

Approved for public release. Distribution is unlinited.

Reference: TM5 6115-457-12 and C9100-IL

Hard time intervals and the related task-hour

Clean

fittings

before

lubricating.

Lubricate

times are based on normal operation. The task-

points indicated by dotted arrow shaft on both

hour time specified is the time you need to do

Clean parts with dryclean-

sides of equipment.

all the services prescribed for a particular

type II or equivalent.

ing SOLVENT (SD),

Dry

interval.

Change the interval if your lubri-

before

lubricating.

Drain crankcase when HOT.

cants are contaminated or if you are operating

Fill and check level.

The lowest level of

the equipment under adverse operating condi-

maintenance authorized to lubricate a point is

tions,

including

longer-than-usual

and

oper-

indicated

by

one

of

the

following:

(C)

ating

hours.

The interval may be extended

or (0) Organizational

Mainte-

Operator/Crew;

during periods of low activity.

If extended,

nance.

adequate

preservation

precautions

must be

taken.

You can help improve this publication.

If you

On-condition

(OC)

intervals

for

oil

changes

find any mistakes or if you know of a way to

shall be determined by the Army Oil Analysis

improve the procedures, please let us know.

Your

letter

or

DA

Form

2028

(Recommended

Program (AOAP)

laboratory and shall be applied

Forms)

unless otherwise notified.

Changes to

Publications

and

Blank

should be mailed directly to:

Commander,

US

Army Troop Support Command, ATTN: AMSTR-MCTS,

Hard time oil

change intervals

will be applied

4300

Goodfellow

Blvd,

St.

Louis,

MO

in the event

AOAP laboratory

support is not

A reply will be furnished to you.

available.

63120-1798.

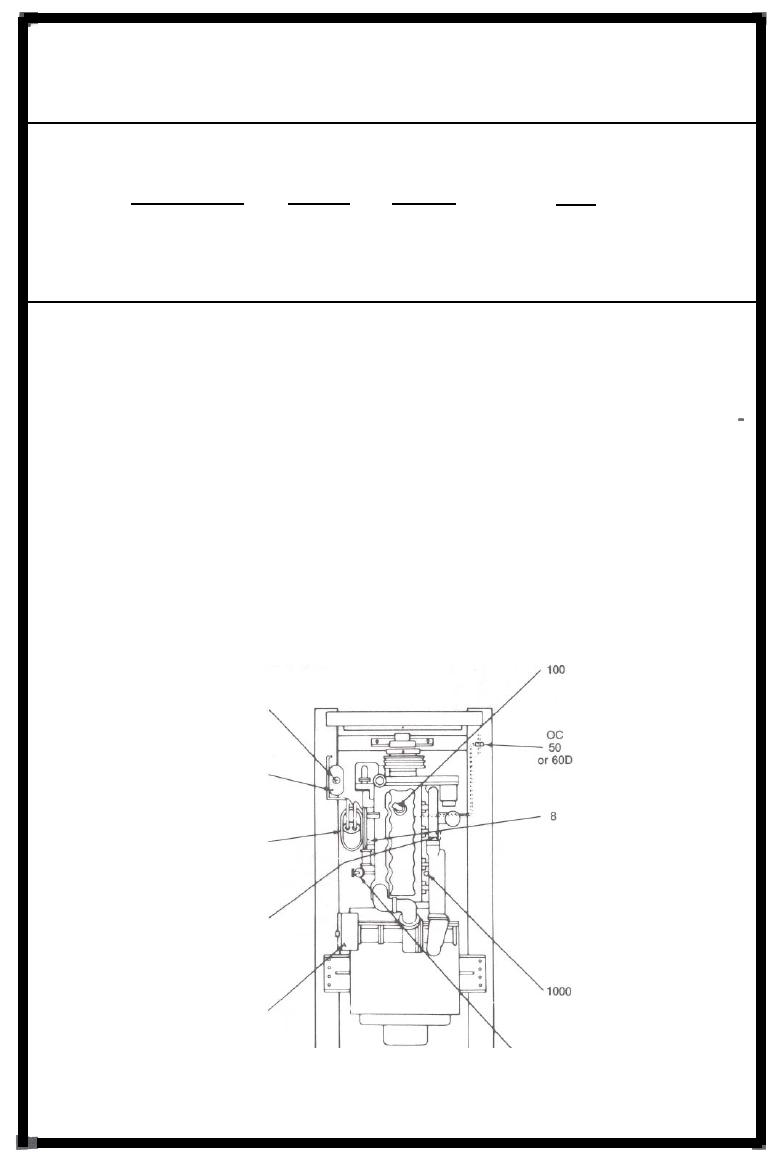

0

LUBRICANT

INTERVAL

0

INTERVAL

LUBRICANT

Crankcase Breather

(0) (Remove, clean,

and install)

OHA

100

Hydraulic Oil Tank

Fill and Level Gage

Crankcase Drain Plug

(C) (Check level)

(01

On-condition

See note 4

AOAP analysis

(Drain and fill)

Hydraulic Oil Tank

1000

(See notes 5 and 6)

Drain Plug (C) (Drain

and fill)

(See note 4

Crankcase Oil Level

Gage (C) (Check

Engine Oil Filters

oc

level.)

(O) AOAP analysis

300

CAUTON:

When OEA

(Disassemble, clean

or6M

oil is used, check

and replace element)

level more often.

(See notes 3, 5,

Oil level

NOTE:

and 6)

may be checked with

engine running.

1000

Hydraulic Oil Filter

(O) (Disassemble,

clean and replace

element) (See note 4)

Governor Actuator

Strainer (O) (Remove

clean, and install)

Engine Air Cleaner

(See note 4)

(Dry type) (No

lubrication required)

U

OE/

Crankcase Oil Fill

HDO

Cap (C) (See key)

CARD 1 OF 2