TM 9-6115-604-34

NAVFAC P-8-633-34

e.

Cold Straightening. Before straightening a crankshaft, a thorough assessment in accordance with step d, above,

should be made to determine the location and type of bend. Short bend misalignment, for example, is associated

with overheating damage to a rod bearing journal. Several damaged rod bearing journals may cause compound

bends, or bends in different directions at different points in the crankshaft. A bend at a rod bearing journal is usually

in the plane of the throw. In many cases, this, and other types of misalignment, can be ground out when regrinding

the main journals rather than straightening. The amount of misalignment that can be ground out depends on the

undersize to which the main journals are to be ground. For example, if a crankshaft is to be ground 0.010 inch (0.25

mm) undersize on the mains, a little less than 0.005 inch (0.13 mm) full length misalignment could be eliminated by

grinding rather than straightening. Good judgment must be exercised when straightening a crankshaft. Straightening

requires metal deformation, and the risk of cracking or breaking the crankshaft increases with the amount of

straightening necessary. It is, therefore, important to weigh this risk before deciding to straighten the crankshaft;

straightening shall be held to a minimum. Tests show that a crankshaft with a full length misalignment of up to 0.005

inch (0.13 mm) TIR can be run in an engine with little adverse effect. Thus, unless it is necessary to regrind the main

journals, a crankshaft with some misalignment can be reused with less risk than d it is straightened. Straightening

should be accomplished using hydraulic straightening press MIL-P-801 78 or an equivalent crankshaft straightening

press with a bed that will allow the ram to traverse a length of at least 70 inches (1 78 cm). Straighten a bent

crankshaft as follows:

(1)

Support the crankshaft in the straightening press on No. 1 and No. 7 main bearing journals (Figure 9-44):

CAUTION

Extreme caution is necessary to prevent over straightening and damage to the crankshaft.

Because of spring back, the crankshaft must be deflected considerably more than the amount of

the misalignment. It is advisable to add the load slowly and to stop and check frequently to

determine the amount of additional straightening required.

(2)

Check the runout of each unsupported main bearing journal to find the point of greatest runout. Apply the

straightening load at this point in a direction opposite to the misalignment (A and B, Figure 9-44).

(3)

Release the straightening load, and check the TIR of the crankshaft. Reapply the straightening load as

necessary until the TIR of the crankshaft is within 0.002 inch (0.05 mm) for both full length and short bend

alignment (Figure 9-39 and Figure 9-44).

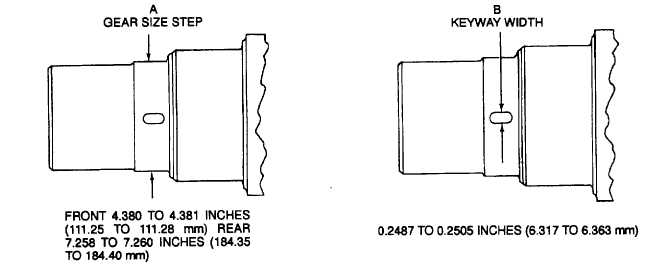

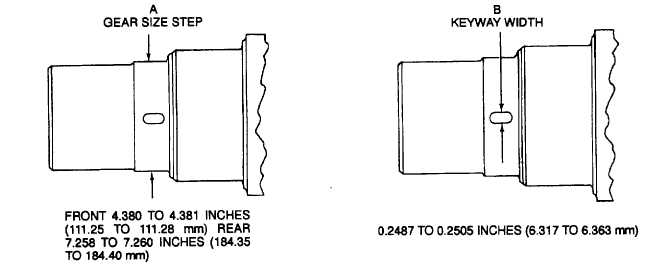

Figure 9-40. Measurement of Gear Step Size and Keyway Width

9-78