ARMY TM 9-6115-464-34

AIR FORCE TO 35C2-3-445-2

NAVY NAVFAC P-8-624-34

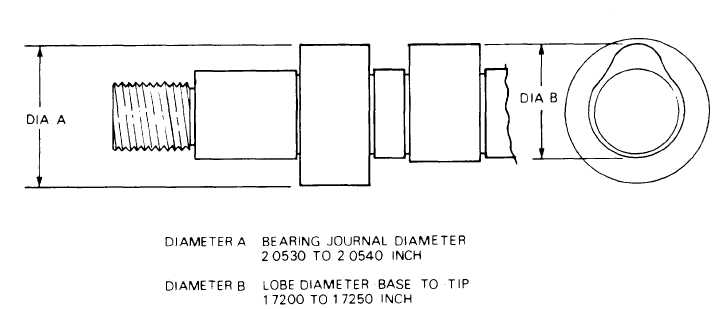

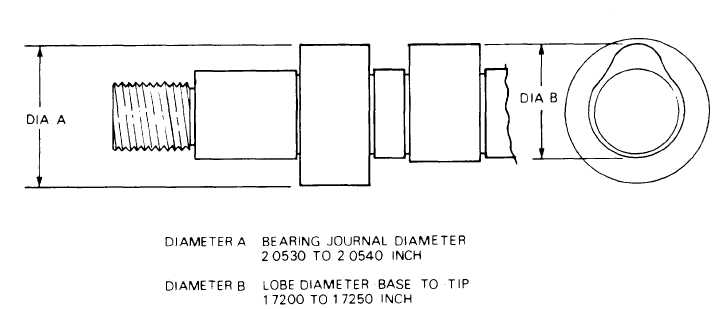

Figure 3-51 .Dimensional Inspection of Camshaft

(11) If dimension obtained in step (8) indicates excessive wear, replace camshaft bearings as follows:

(a) Using a suitable press, remove camshaft bearings from cylinder block.

CAUTION

Make sure that the replacement bearings are installed so that oil holes match with oil

ports in cylinder block. Failure to observe this caution could result in equipment

damage.

(b) Press replacement bearings into cylinder block.

d. Assembly.

(1) Install thrust plate (7, figure 3–50), key (6) and press shaft (5) into gear.

(2) Install support drive gear (4) onto arbor press with nut (3).

(3) Torque nut (3) to 130 ft-lbs.

e. Installation.

CAUTION

Make sure that timing mark on camshaft drive gear mates with timing mark on

crankshaft gear. Failure to observe this caution could result in equipment damage.

NOTE

Valve tappets must be in the UP position to install camshaft.

(1) Refer to figure 3-45 to insure proper timing of camshaft gear to crankshaft gear is obtained.

(2) Install valve tappets (35, figure 3-46).

3-119