ARMY TM 9-6115-464-12

AIR FORCE TO 35C2-3-445-1

NAVY NAVFAC P-8-624-12

4-59 ROCKER ARM ASSEMBLY.

a.

Remove air cleaner assembly (paragraph 4-51).

b. Thoroughly clean the valve cover and surrounding area.

c.

Remove capscrews and washers to remove valve cover and gasket. Discard gasket.

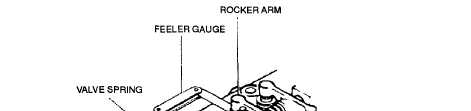

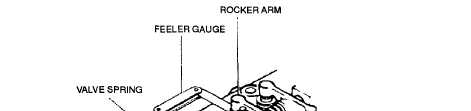

d. Inspect valve rocker arm assembly as follows (Figure 4-37).

(1) Check adjusting screw, rocker arms, and shaft for cracks and indications of excessive wear.

(2) Inspect springs for distortion, cracks, and breaks.

(3) Check the oil hole in each rocker arm for plugging. Use a small wire and compressed air to clean plugged

oil holes.

e.

If damage or excessive wear of the rocker arm assembly is present, notify higher level maintenance.

f.

Install gasket and valve cover and secure with washers and capscrews.

g.

Install breather and breather tube.

4-60 VALVE TAPPET CLEARANCE ADJUSTMENT.

a.

b.

c.

d.

e.

f.

g.

Refer to paragraph 2-6 and operate the engine until the coolant temperature gauge indicates normal operating

temperature.

Refer to paragraph 4-59 and remove the valve cover.

Bar the engine over by hand until both the intake and exhaust valves on No. 1 cylinder are completely dosed.

Using a feeler gauge, check clearance between the valve stem and the rocker arm on both intake and

exhaust valves (Figure 4-37). Clearance should be 0.015 hot.

If the clearance is not as specified, use a suitable wrench to rotate adjusting screw until proper clearance is

obtained.

Check and, if necessary, adjust the clearance of the valves on the remaining cylinders as outlined in paragraphs

c., d., and e. above, following the firing order of 1, 2, 4, 3.

When all valves are properly adjusted, refer to paragraph 4-54 and install the valve cover.

Figure 4-37. Rocker arm assembly inspection and valve tappet clearance adjustment

4-81