TM5-6115-465-34

NAVFAC P-8-625-34

T.O.35C2-3-446-2

TM 06858B/06859D-34

(b) One direction shall give an indication

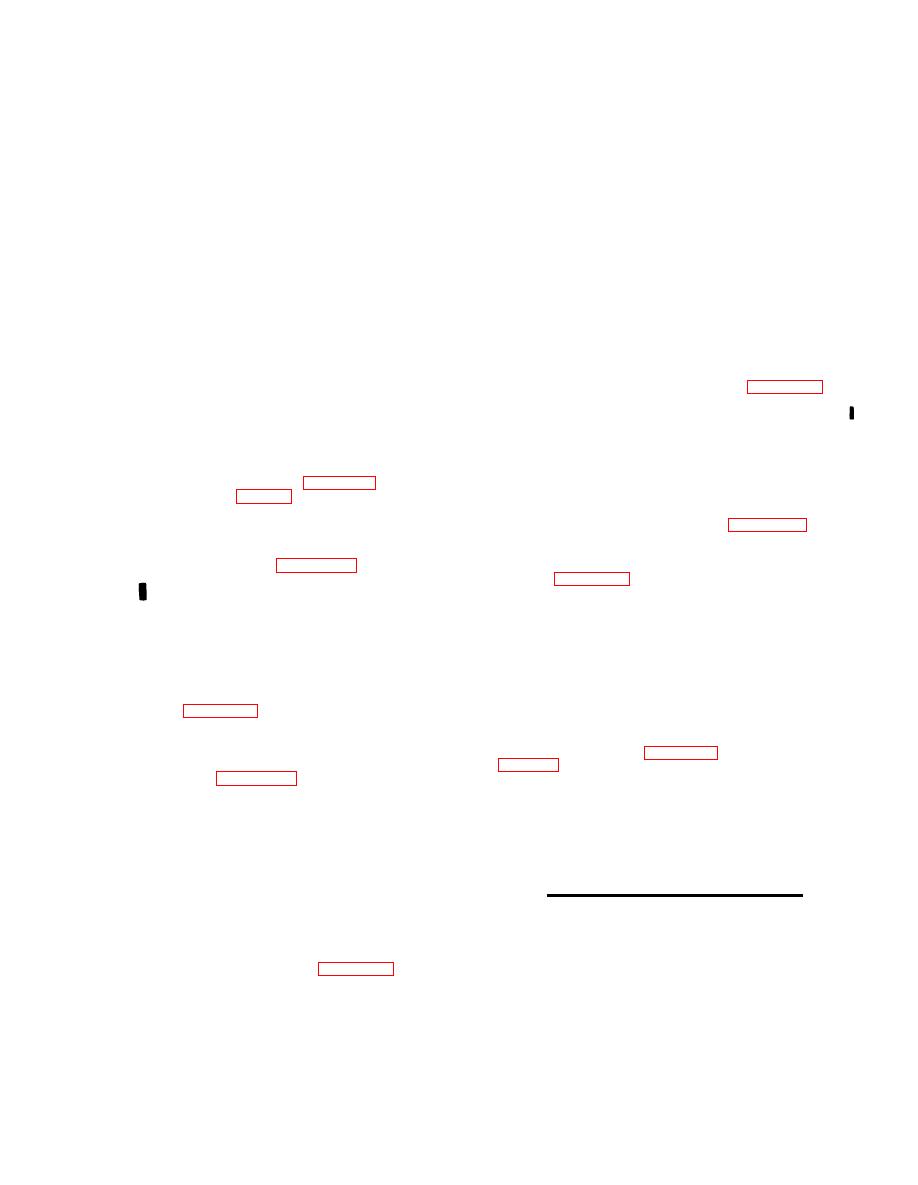

(a) Connect static exciter and voltage

regulator assembly into test circuit shown in figure

of less than 100 ohms. The other direction shall

5-34.

give an indication of one megohm or more. There

shall be no indication of discontinuity in either

direction.

(b) Adjust power source until VI shows

95 Vac (any frequency between 50 and 400 Hz).

(c) Replace defective semiconductors.

(5) Inspect terminal board assembly for

(c) Check for 22 Vdc across R15 (con-

nect voltmeter V2, positive side to cathode of CR 11,

cracks, burns, and corroded terminals. Replace

and negative side to heat sink where CR4-CR6 are

defective terminal board assembly.

mounted).

(6) Inspect transformers for cracks, corro-

(2) Conduct power circuit bench test as follows:

sion, and evidence of shorting or overheating. Check

continuity of coils using an ohmmeter. There shall

(a) Install static exciter and voltage regu-

be no sign of open circuit.

lator assembly into test circuit shown in figure 5-35.

(7) Replace defective transformers.

(b) Adjust power source to 208 Vac at the

(8) Inspect voltage regulator assembly for

burned or damaged components.

(c) For 400 Hz units only apply 50-76 Vat,

400 Hz to terminals A and B of connector J9.

(9) Electrically check voltage regulator as-

sembly components using figure 5-31 or 5-32 as a

(d) Voltmeter V2 should indicate 48 Vdc

guide. Refer to table 5-1 for capacitance and resis-

(3) Conduct boost circuit bench test as follows:

tance value of components.

(a) With chassis cover (4, figure 5-30)

(10) If any voltage regulator components

removed, connect positive lead of voltmeter to heat

sink where CR 1-CR3 are mounted. Connect negative

must be replaced or encapsulating coating repaired

lead to heat sink where CR4-CR6 are mounted. (See

or replaced, refer to Appendix A references for

item 17, figure 5-30).

detailed procedures. Repair/replace encapsulation

by applying 0.020 inch (rein) coating of polyureathane

resin (scotchcast 221, Minnesota Mining and Mfg.

(b) Apply 12 Vac (any frequency between

50 and 400 Hz) to pins A and B of connector J13.

Co. or equal).

(11) Inspect wiring harness for damaged con-

(c) Voltmeter connected across heat sinks

nectors and terminals, burns, broken wires, and

should indicate 9.3 Vdc.

other damage.

(d) Remove 12 Vac from pins A and B and

(12) Check individual wires for continuity

connect to E and F, then to J and K. In each case,

using figure 5-33 as a guide.

voltmeter should indicate 9.3 Vdc.

(4) If the requirements of any test are not met,

(13 ) If the wiring harness has sustained dam-

age and requires repair or rebuild, refer to figure

check components using figure 5-31 or 5-32 and

5-33 for layout, identification and material require-

ments and Appendix A references for detailed solder-

before installing the static exciter and voltage regula-

ing and replacement. procedures.

tor assembly.

g. Installation. Install static exciter and volt -

e. Assembly. Assemble static exciter and

voltage regulator assembly in reverse order of re-

age regulator assembly in reverse order of removal

moval procedures.

procedures.

f.

5-14.

Testing.

RELAY TABLE COMPONENTS AIIJUST-

MENTS.

(1) Perform sensing circuit bench test as

a. General. After maintenance has been per-

follows :

formed on any of the relay table components, the

NOTE

appropriate adjustments shall be performed.

The chassis cover .(4, figure 5-30) must

be removed to perform the bench test.

b.

Voltage Adjustment.

Change 2

5-47