NOTES:

FOR OPERATION OF EQUIPMENT IN PROTRACTED

4.

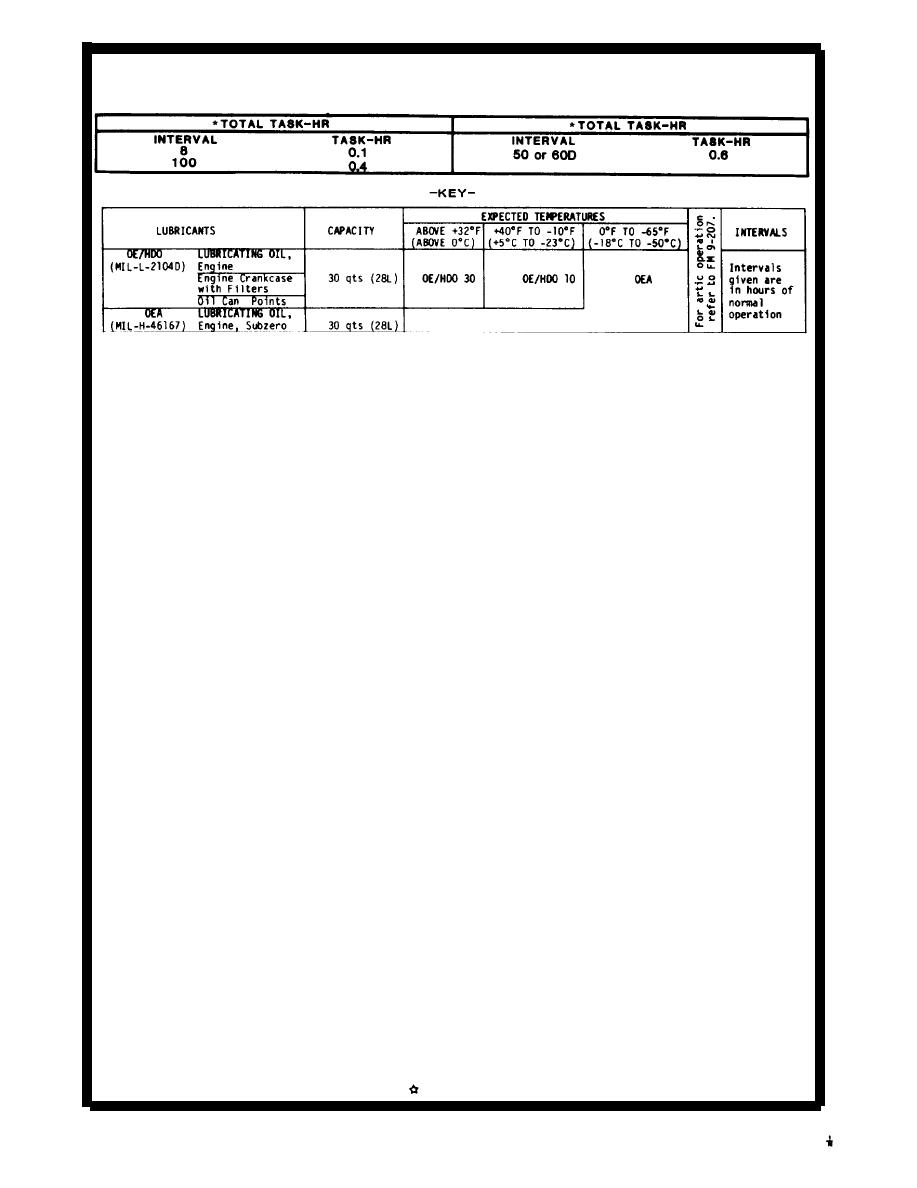

CRANKCASE OIL.

A sample of the oil shall

COLD TEMPERATURES BELOW -10F (-23C). Remove

b e sent to an AOAP laboratory for analysis at

lubricants prescribed in the key for tempera-

a n interval of 50 hours or 60 days.

Refer to

Clean parts with

tures above -10F (-23C).

TB 43-0210 for sampling requirements.

drycleaning SOLVENT (SD), type II or equiva-

lent.

Lubricate with lubricants specified in

5.

W h e n AOAP laboratory support is not avail-

the key for temperatures 0F to -65F.

able, d r a i n a n d r e f i l l c r a n k c a s e o i l a t 3 0 0

hours or 6 months.

E v e r y 100 hours lubricate

2.

OIL CAN POINTS.

and a l l

hinges,

latches, control

exposed adjusting threads with OE-HDO.

C o p y of this Lubrication Order will remain with

the equipment at all times; instructions con-

Oil filter replacement

3.

ENGINE OIL FILTER.

tained herein are mandatory.

interval shall aline with on-condition AOAP

a n a l y s i s or hard time oil change requirements.

By Order of the Secretary of the Army:

After installing a new

See notes 4 and 5.

filter element, fill crankcase, operate engine

Shut

for 5 minutes, and check for leaks.

JOHN A. WICKHAM, JR.

engine down, c h e c k c r a n k c a s e o i l l e v e l , a n d

General, United States Army

bring to full mark.

Chief of Staff

Official:

R. L. DILWORTH

Brigadier General, United States Army

The Adjutant General

DISTRIBUTION:

To be distributed in accordance with DA Form

12-25A, Operator and Organizational Maintenance

requirements for Generator Set, Diesel Driven,

120/208V, 240/416V, 100KW, 50/60 HZ, 3PH, 4 Wire

(MEP-008B).

U.S. GOVERNMENT PRINTING OFFICE: 1986-181-028/40344

L05-6115-600-12

CARD 2 OF 2

PIN: 05768

000