ARMY TM 9-6115-464—34

AIR FORCE 35C2-3-44-2

NAVY NAVFAC P-8-624-34

2.

4.

6.

7.

8.

10.

NOTES:

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

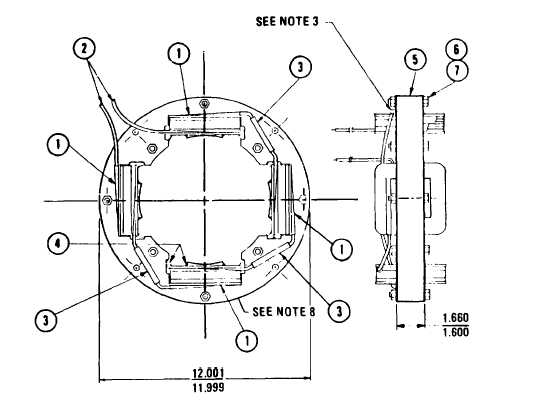

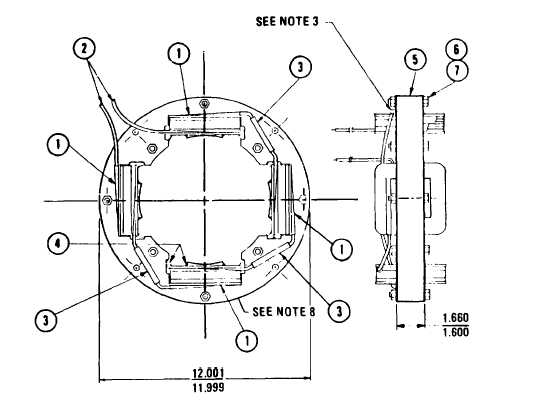

Bobbin, wound

Wire

Insulation sleeving

Insulating compound

Lamination, stator

Screw, cap

Nut, self-locking

Bobbin (not wound)

Wire

Yard, cord

INTERPRET DRAWING PER MIL-STD-100.

SOLDERING SHALL BE IN ACCORDANCE WITH MIL-STD-454. REQUIREMENTS.

STACK LAMINATIONS, FIND NO .5, UNDER 3 TONS ± 10%.

TORQUE CAP SCREWS, FIND NO. 6, TO 16+1 FT-LBS, WHILE LAMINATIONS ARE

UNDER PRESSURE.

AFTER ASSEMBLY, SPRAY WITH ONE COAT OF VARNISH IN ACCORDANCE

WITH MIL-V-173.

SLEEVING, FIND NO. 3, SHALL BE SUFFICIENT TO COVERED SOLDERED

CONNECTIONS.

MARK:

30554-72-2430

MFG: (CODE IDENT NO.)

IN ACCORDANCE WITH MIL-M-13231 , GROUP 1,2, OR 3 CHARACTERS SHALL BE

.12 MIN. HIGH AND LOCATED AS SHOWN.

GROUND INSULATION: GREATER THAN 1000 MEGOHMS. HIGH POTENTIAL: 1500 VOLTS.

WIND BOBBIN, FIND NO. 8, WITH 200 TURNS OF WIRE, FIND NO. 9.

APPLY A MINIMUM OF 2 LAYERS OF TAPE, FIND NO. 10, WITH OVERLAPPING.

OUTSIDE SURFACE OF WINDINGS SHALL BE LESS THAN OUTSIDE FLANGES OF BOBBIN.

BENCH TEST RESISTANCE: .61 OHMS.

Figure 3-146. Generator Exciter Stator Winding Procedures

(Sheet 1 of 2)

3-306

1.

1.

3 .

5.

9 .